A great place to visit for ideas on simple woodworking projects for storage.

I wanted to build a jig for my table saw and it took me a while to remove the riving knife. I couldn’t find anywhere online any information on how to do it and a few DW745 images I realised ther are a few different versions of this mechanism.

At the beginning I thought I could just pull the riving knife up, after unscrewing the bolt on the side. It became apparent that it wouldn’t come off that easily. I had to unscrew the holder (four screws in a 2×2 formation). These four screws were a pain to remove and took a few attempts with different tools.

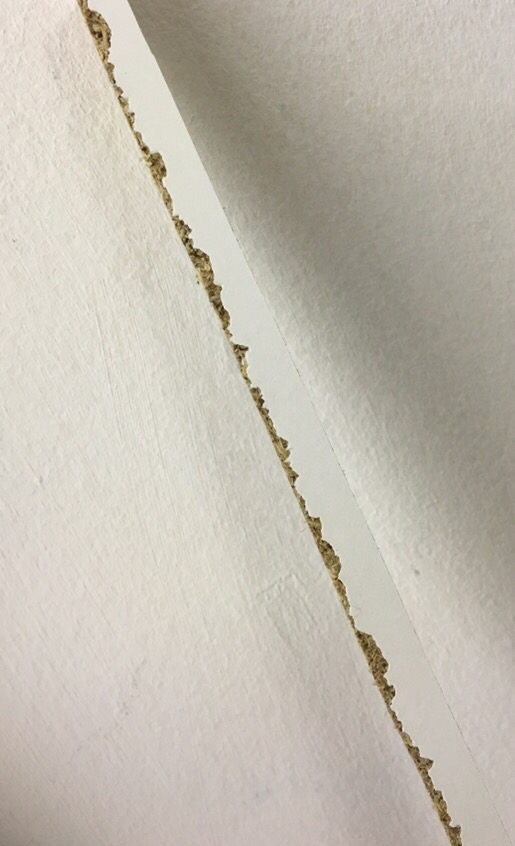

I did managed to remove the screws in the end and got the riving knife out. It looks like there is a latch mechanism to prevent the riving knife flying out if the side bolt gets lose. This mechanism is quite simple: there is a hole on the body of the riving knife and a peg on a spring mechanism on the holder.

You can see the peg/latch mechanism in the photo below. It’s a little rectangle block with a little round peg on the lower left corner. The round peg locks the riving knife in place. The rectangle block is on a spring and pushes against the riving knife.

I guess the way to remove the riving knife is to push a very thin metal strip on the side of the riving knife that’s near the motor. That will push the latching mechanism in and the tiny peg will be out of the hole. Then you can pull the riving knife up.

I hope this post helps someone with this problem!

I just came across this interesting blog post on onboarding new team members.

https://kateheddleston.com/blog/onboarding-and-the-cost-of-team-debt

Written by Kate Heddleston, a programmer who also enjoys talking about team management.

I used my jigsaw, Bosch PST 900 PEL to cut a shelf from IKEA. That was a few months ago, when I didn’t own table saw.

I recently got a nice table saw, DeWalt DW745 with a brand new Freud Pro LO40M blade and tried to see how good this cut would have been. I used the off cut of the original cut.

The left side is the Bosch cut, using the finest Bosch blade I had. The right side is the DeWalt table saw cut… No comparison really. No chipping, no marks. As good as a factory side!

The DeWalt is a fantastic piece of equipment. Every cut is perfect and it’s such very robust and extremely easy to use. The blade that comes with it was a bit to rough for my taste, as this table saw is meant to be for construction work. Replacing it with a Freud blade, made all the cuts a lot smoother.

I ordered a small adaptor from Amazon. I was expecting it to arrive in an envelope, only to find something bigger stuck in my mailbox…

My expectations were immediately raised. I opened the big package, only to find a smaller package…

That itself contained a tiny little adaptor:

This adaptor is really tiny… Was that much packaging really worth it?